Total Build Time: 1290 Hours

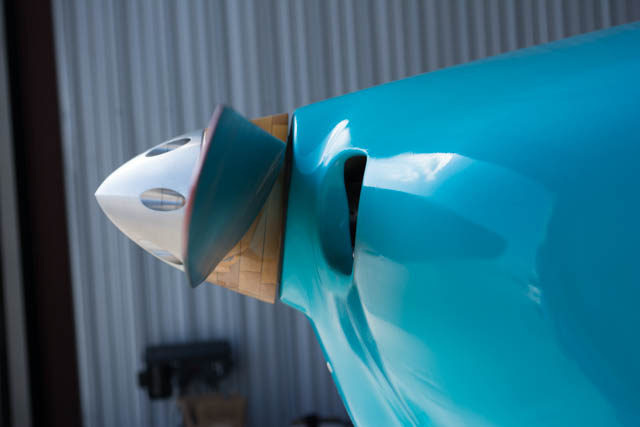

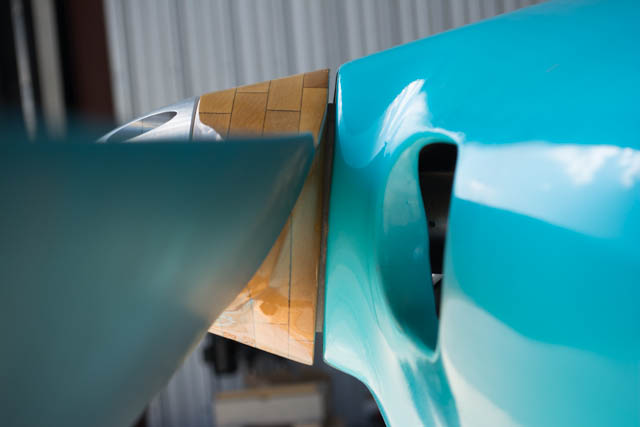

After about 2 years of having the engine and cowling fitted to the airframe, when I put the cowling on the airplane I noticed that the prop hub was rubbing on the cowling.

What can be seen in the above photo is the top and bottom of the propeller hub is sagging about 1/4 inch below the matching lines on the cowling. This can mean only one thing since the geometry of the cowling hasn’t changed…. the engine is sagging on the engine mount.

I quickly determined the reason why…

The engine mount bushings were extruding over the engine mount, causing the bottom mounts to compress inwards resulting in the propeller being lower relative to the airframe.

To solve this problem I decided to add washers of a larger diameter than the bushings (and larger than the built-in washers of the engine mount). Rather than completely remove the engine to accomplish this, I slotted some washers to slide over the bolts:

This worked well. I loosened the engine mount bolts and jacked up the engine enough to give me a gap to slide the slotted washers into place. Once secured, the bushing are much better supported:

I also noticed a seperate issue on the nut-side of the same bolts. The washers called for in the plans (and provided in the engine kit) are of significantly different inner-hole diameter… this picture is of the front-side washers installed per the plans:

I decided that I didn’t like the lack of contact area between the washer under the nut and the washers supporting the engine mount bushing. So I found myself some new washers with a smaller center hole diameter:

In the picture above, the center washer is correct for under the nut. The left washer is the one called in the plans/provided in the kit, and the right washer is once I found that has a smaller center hole diameter that matches the center washer. Once installed, I had good contact area between all of the installed washers:

The end result raised the prop hub back to its original position, stopped the prop hub from rubbing on the cowling and should help keep the engine from sagging in the future.

This has been an issue noted by many other builders/owners of the Aerovee engine and some have taken similar steps and/or replaced the bushing with more rigid bushings less likely to compress over time. This is probably a change I’ll make the next time I remove the engine from the airframe for service.